SEGGER continuously advances its products. First, SEGGER uses their own tools, better products mean better output. Second, the R&D departments also value customer feedback and place great ideas onto their to-do lists. In this case, SEGGER’s Embedded Experts identified how they could help VIESSMANN, an existing SEGGER customer, who was aiming to minimize the time to program the QSPI flash used in their products. VIESSMANN designs and manufactures innovative industrial heating and cooling systems. You can read more about them at the end of this article.

SEGGER’s Flasher PRO increases production reliability for Viessmann

Published: April 7th, 2021

The production line

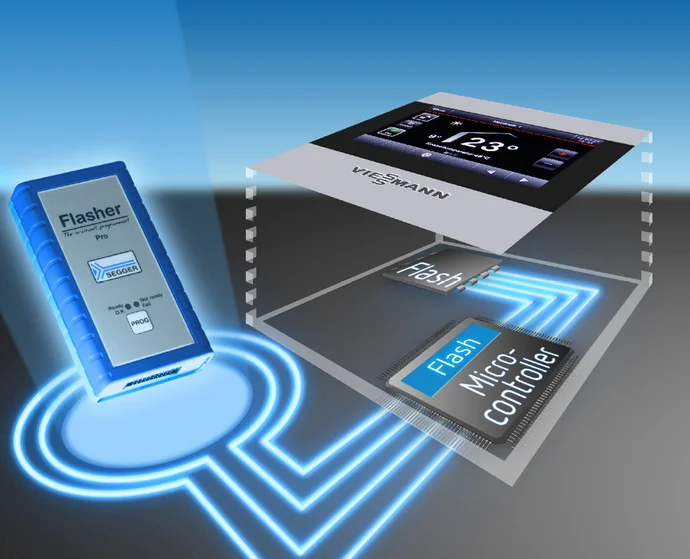

VIESSMANN relies for most of its products on easy-to-operate touch display units with the firmware running on a microcontroller. The touch displays present device settings and statistics about the amount of generated power and the used power source.

Production requires that the blank flash memory of these units be programmed and verified before moving to system test and shipment. As the firmware image to program is comparatively large, the time spent programming directly affects the number of units that can be produced in an hour, day, or any time period.

VIESSMANN selected SEGGER Flasher to program the units, with each unit taking 120 seconds to program at the time. Having planned a production rate of one unit every 60 seconds, VIESSMANN deployed two Flashers to program two units in parallel.

For sure, this setup achieves the production goal, but what other options are there to achieve more headroom in case of failures? Both programming stations consist of a PC, to which the flasher and a small needle bed adapter, which transfers the signals of the flasher to the PCB, are connected via USB. We know that the crash of a PC, however unlikely, can never be completely ruled out.

Improving productivity

SEGGER started to look at ways to reduce programming time. VIESSMANN had not updated the firmware of their production Flasher since purchase. This is understandable, as disturbing a working production line could lead to unwanted downtime: It honors the time-old mantra of “If it’s not broken, don’t fix it!”.

The first option is obvious: update the Flasher to use the latest SEGGER software release, including new firmware for the Flasher unit. Unlike programming solutions from other vendors, there is no cost for doing this, all software releases for SEGGER J-Link and Flasher products are entirely free of charge and total cost of ownership is the initial purchase price!

In addition, VIESSMANN shipped SEGGER a sample unit for experimentation, so that SEGGER’s flasher group could analyze further potential for improvements. Using their experience, a new solution for VIESSMANN quickly emerged:

- The programming algorithm for their QSPI flash was optimized.

- The page size being programmed was increased from 512 to 2048 bytes, adding multipage loading at the same time.

SEGGER Turbo Mode was activated so that programming runs in parallel with downloading data.

These simple modifications reduced the 120-second programming time to just 70 seconds. Because VIESSMANN’s production line has remained unchanged for some time, it used an older hardware version of the Flasher Pro. SEGGER improves not just its software, it also continually improves the performance and features of its hardware by selecting the best technology available as it comes to market and is proven reliable.

Replacing the Flasher Pro version 4 by a Flasher Pro version 5 brought programming time down to 60 seconds per unit, cutting the original value in half. In VIESSMANN’s dual-station production line, one Flasher Pro can be used as a backup from now on, significantly increasing production reliability.

Conclusion

VIESSMANN is very satisfied with the results achieved by SEGGER since production has gained more breathing space with the reduction in programming time. Production requires only a single Flasher to achieve the required production throughput, leaving the second station available as a backup in case of primary failure. Of course, all improvements made during this study are now available in SEGGER’s Flasher and J-Link software packs, free to all users.

In addition to the specific use case described here, there are potentially other use cases in which the time savings generated could help VIESSMANN in the future. We will keep you informed about the benefits SEGGER’s Flasher – and the also used GUI emWin, the RTOS embOS and the file system emFile – will bring to the company in the future.

SEGGER’s Embedded Experts are always looking for ways to improve any product – customer feedback is highly appreciated and can be mailed to info@segger.com.

Jan. 2021 | 3:00 min

Flasher Pro — QSPI flash programming

Contact us for your own success story

If this success story inspired you, let's talk about how we can help you achieve similar results.

• Tailored solutions for your specific requirements

• Expert support from development to production

• Reliable tools that let you focus on what matters most

We look forward to hearing from you.