SEGGER emNet supports Siemens’ smart Ethernet-APL field devices for the process industry

Published: July 29th, 2021

Process plants are operated across a wide range of industries. This includes producers of food, wood, steel, metal-based products, chemicals and many more. These factories have a typical lifespan of more than 20 years and must be safe for people, product and environment. The vision of Industry 4.0 or Industrial Internet of Things (IIoT) is to connect all sensors and actuators to a converged Information Technology/Operational Technology (IT/OT) network and control them using a process control system from the outside.

As more devices become connected to the network, a wider, real-time view of the plant is available through management systems. Optimization based on the collected data delivers significant productivity gains while reducing operating costs and energy consumption.

An extended physical Ethernet layer and SEGGER’s IP stack emNet lay the groundwork for future smart field devices from Siemens, one of the largest suppliers of sensors and actuators for the process industry.

Introduction

While IP-based communication is standard for the Internet, and Ethernet is the de facto IT communication standard in companies, M2M (machine to machine) communication in general has specific requirements that prevent the unaltered use of the Ethernet standard. In particular, it does not meet the requirements in the field of process automation without modification: Explosion hazards in hazardous areas and harsh conditions require adaptations to transfer the proven benefits of Ethernet in IT to OT. For example, there are limits on power consumption in explosive environments which are not met by standard Ethernet specifications.

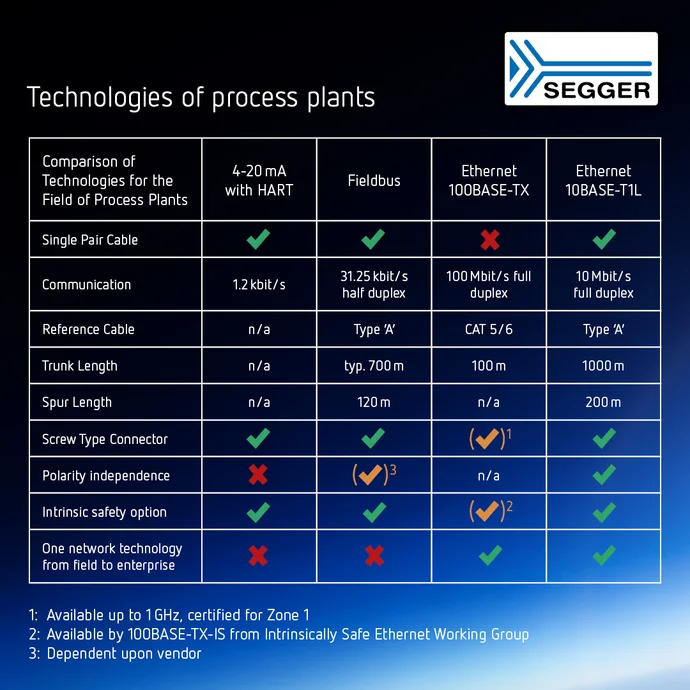

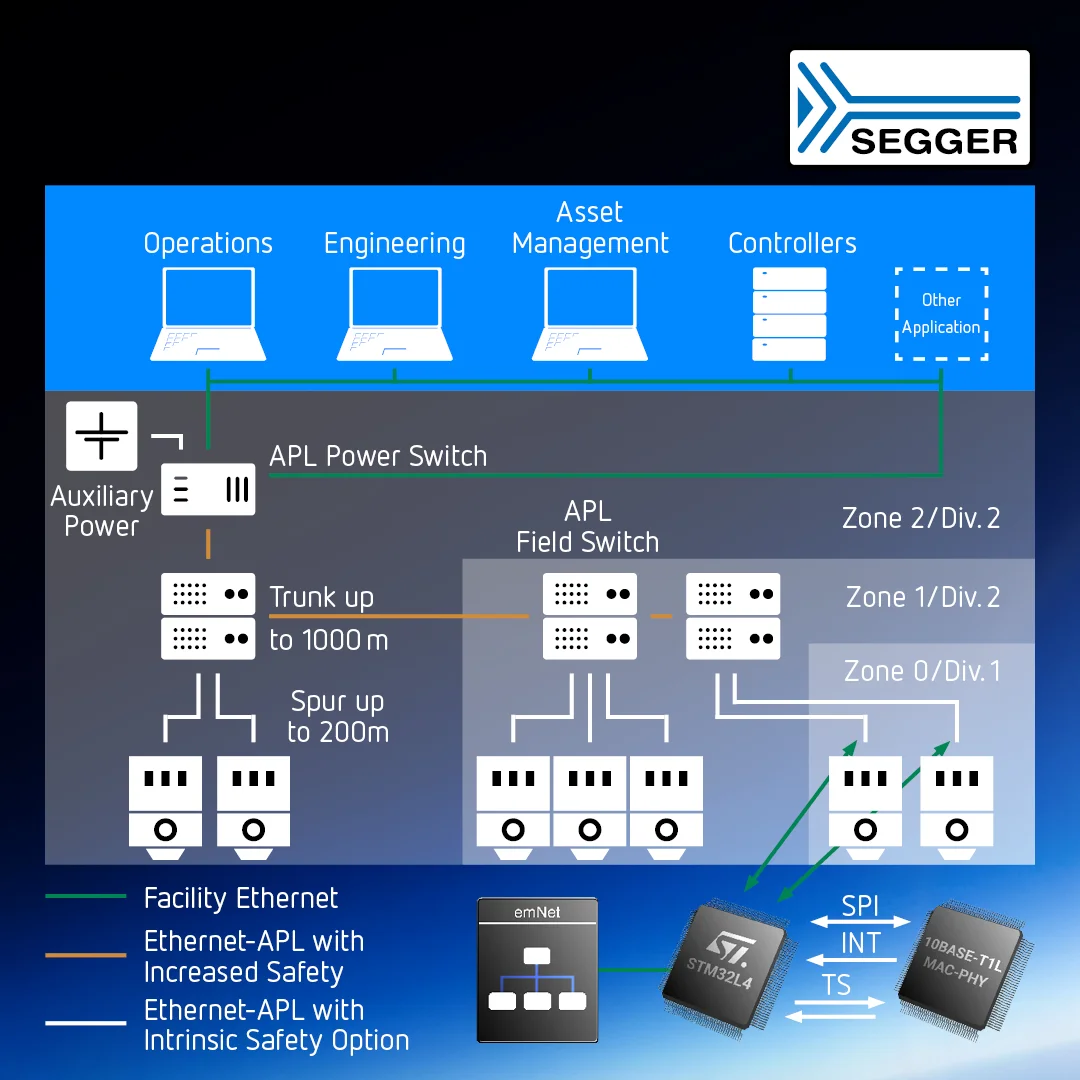

To solve these challenges, a consortium of all major manufacturers and organizations (see appendix) has defined a new Ethernet standard: Ethernet-APL (Advanced Physical Layer) is an extended physical layer for single-pair Ethernet (SPE), based on 10BASE-T1L. It communicates over a cable length of up to 1000 m at 10 Mbit/s, full-duplex, which is more than 300 times faster than current technologies such as HART or Fieldbus (Figure 1). It is the logical extension for Ethernet and provides the necessary features for reliable operation in the field of a process plant. Ethernet-APL is a physical layer that will be able to support EtherNet/IP, HART-IP, OPC-UA, PROFINET or any other higher-level protocol. Figure 2 shows an example of a converged IT/OT network based on Ethernet-APL. Ethernet-APL that has the potential to become the standard long-term technology for the entire process automation industry.

Explosive environments request Ultra-low-power devices

To achieve the vision of connecting all sensors and actuators, there are system engineering challenges as some of these devices are limited in electrical power and space when in explosive environments. In particular, the power supply output on an APL spur (connecting APL field switches to the field devices, see Figure 2) is limited to 540 mW at 15 VDC. This power limitation and the requirement to fulfill ex-requirements for an intrinsically save device makes the use of an ultra-low-power (ULP) microcontroller mandatory. To maximize power savings, ULP MCUs are resource-constrained: They typically do not have an integrated MAC, and are constrained to lower clock frequencies and smaller memory footprint.

Why did Siemens choose SEGGER’s emNet for its smart field devices?

SEGGER has integrated the driver for the ultra-low-power microcontroller STM32L4 and the combined MAC-PHY Ethernet controller ADIN1110 to run emNet. This represents a convincing solution platform for Siemens (Figure 2). The reason is simple: emNet offers high performance even on the smallest microcontrollers. The industry-leading dual IPv4/IPv6 TCP/IP stack for embedded systems was developed from the ground up for resource-constrained embedded applications and is known for its low memory requirements combined with flexibility and expandability. For example, the complete stack on a Cortex-M-based microcontroller occupies less than 20 KB of ROM and only 1.5 KB of RAM (without read/write buffers).

emNet offers easy integration without configuration effort. Its design, specifically targeted at embedded devices, makes it highly efficient in terms of packet processing speed. This means that even small, low-frequency microcontrollers deliver excellent network performance.

An example for performance-optimizing features of emNet is UDP flood protection. This feature helps to save execution time on incoming data that is to be discarded anyway. If the device is part of a crowded network, this optimization frees up CPU time for other tasks. In this blog article, you can find more details on this topic.

Last but not least, emNet’s flexible PHY driver layer provides support for virtually any Ethernet PHY transceiver. A generic PHY driver compatible with almost all single-port PHYs on the market that follow the IEEE 802.3u standard is included in emNet. Support for other PHY-like devices such as Ethernet switches is also possible. Please check out SEGGER’s emNet website for more technical details and performance analysis.

emNet will support drastic industry improvements

Ethernet-APL will dramatically change the industry by greatly improving operational efficiency through seamless Ethernet connectivity to field-level assets. 10BASE-T1L solves the challenges that have previously limited the use of Ethernet in field assets. These challenges include power, bandwidth, cabling, distance, data islands, and intrinsically safe Zone 0 (hazardous area) applications. By solving these challenges in both retrofit and greenfield installations, 10BASE-T1L enables new insights into plant health that were previously unavailable and communicates them seamlessly to the control plane and to the cloud or a private server. These new insights open up new opportunities for data analytics, operational insights and productivity improvements through a converged Ethernet network from assets in the field, also to the cloud or private server.

To make Industry 4.0 a reality for the process industry, SIEMENS will provide smart field devices. They include a MAC/PHY chip and an ultra-low power microcontroller, running SEGGER’s emNet as the best available IP stack that combines lowest power consumption with the highest reliability.

Appendix: How the new Ethernet-APL standard was created

The agreement to develop the Ethernet-APL technology under “The APL Project” was established in 2018 and is backed by the leading industry standard development organizations (SDOs) FieldComm Group, ODVA, OPC Foundation, and PROFIBUS & PROFINET International, as well as by major industry suppliers of process automation, including ABB, Emerson, Endress+Hauser, Krohne, Pepperl+Fuchs, Phoenix Contact, R.Stahl, Rockwell Automation, Samson, Siemens, Vega, and Yokogawa.

The main objective of the cooperation is the specification of one single physical layer that meets the requirements of process automation. To achieve this goal, representatives of project members have been working on enhancements of IEEE and IEC standards underlying the technology, have been collaborating on the development of a port profile to fit the specific requirements of the process industries, and are participating in working groups to create or enhance the SDO’s relevant specifications and guideline documents. The finalization of all these standards and specifications makes this technology accessible to all users and vendors.

Being based on existing and widely used standards, with the cooperation of large companies and the most important SDOs in process automation, strong market adoption of the single physical layer Ethernet-APL is anticipated.

Contact us for your own success story

If this success story inspired you, let's talk about how we can help you achieve similar results.

• Tailored solutions for your specific requirements

• Expert support from development to production

• Reliable tools that let you focus on what matters most

We look forward to hearing from you.